Carbon Steel Perforated Sheets are not alloy steel. Thus it does not include substantial amounts of other elements than iron; it does not contain High Levels of Chromium, Molybdenum, or other Alloying Elements.

As the Mild Steel Perforated Sheets have less carbon, it is more ductile, machinable, and weldable than high carbon and other steels; nevertheless, it is almost challenging to harden and strengthen by heating and quenching.

Because of the low carbon content, it has less carbon and other alloying elements to prevent dislocations in its crystal structure, resulting in lower tensile strength than high carbon and alloy steels. Mild steel Perforated Sheet is additionally magnetic due to its high iron and ferrite content. Due to the lack of alloying elements in stainless steel, iron in mild steel is susceptible to oxidation if not adequately coated.

MS Perforated Sheet Manufacturer, Mild Steel CR Perforated Sheet, Mild Steel Perforated Sheet at Best Price, Cut To Size Mild Steel Perforated Sheets, Mild Steel Hexagonal Hole Perforated Sheets, MS Industrial Perforated Sheets Stockist in Mumbai, India.

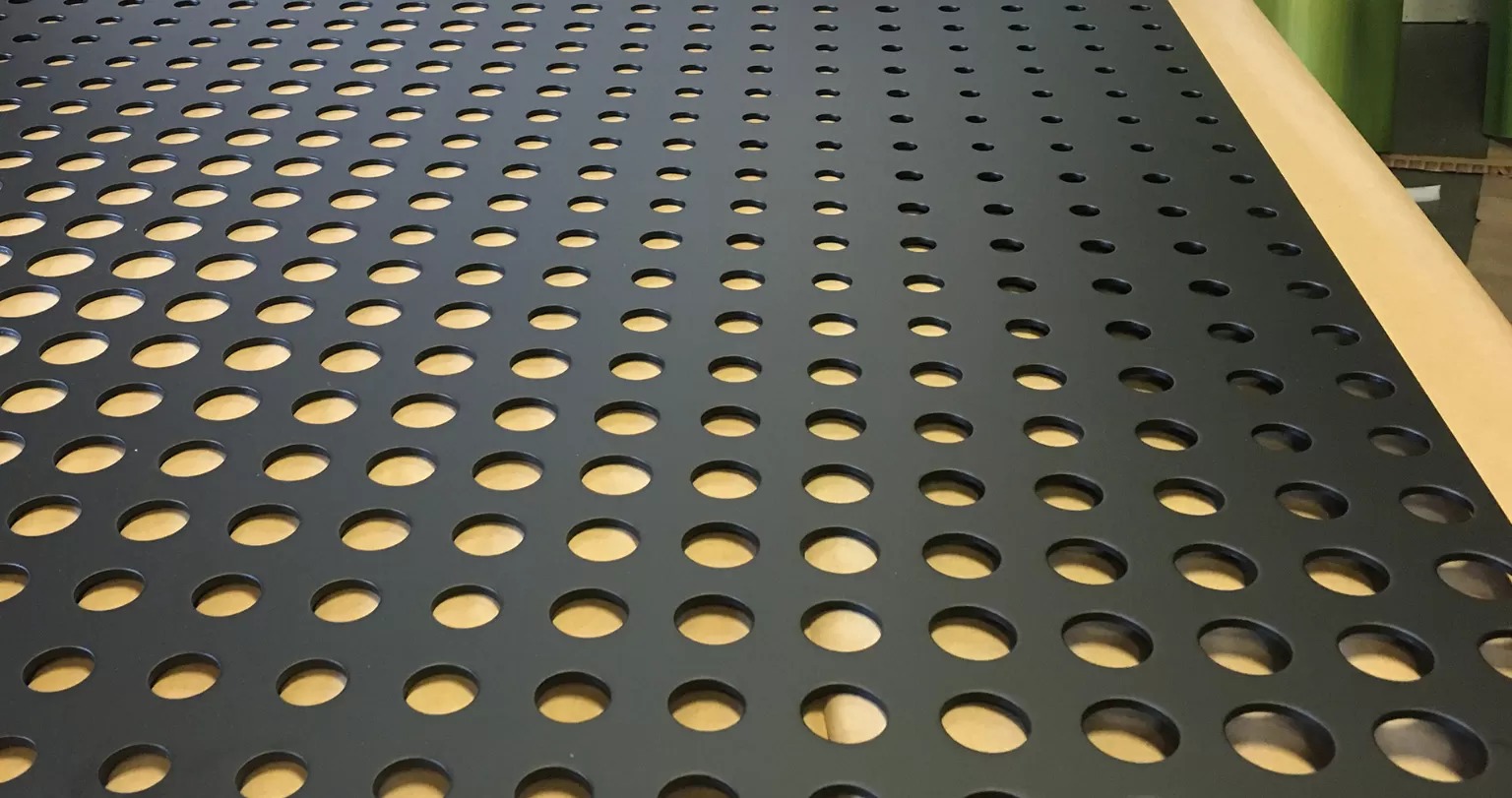

A Round Hole Mild Steel Perforated Sheet is frequently applicable in structural applications. Mainly if they were applied as structural repairs or other home renovation tasks. Mild steel has a small quantity of carbon, which gives it a robust structure and makes it simple to weld to the desired shape, pattern, and size. The range of sheets now being offered is used as flooring in locations that employ large, heavy machinery. This metal must have been perforated for proper transmission of liquid, light, air, or sound.

| Specification | ASTM / ASME |

| Item | Perforated sheet(Hot rolled, cold rolled) |

| Thickness | 0,4 mm to 12 mm. |

| Size | 1/32?, 1/16?, 3/32?, 1/8?, 3/16? |

| Width | 100 mm – 2000 mm |

| Length | As Required |

| Holes Type | Round, Square, Oblong, Rectangular, Capsule, Hexagonal, Dimpled, Lipped |

| Hardness | Half Hard, Quarter Hard, Soft, Hard, Spring Hard |

| Value added services for | Waterjet Cutting, Plasma Cutting, Laser Cutting, Bending and mechanical Processing, Edge Preparation, Welding, Sawing and Shearing |